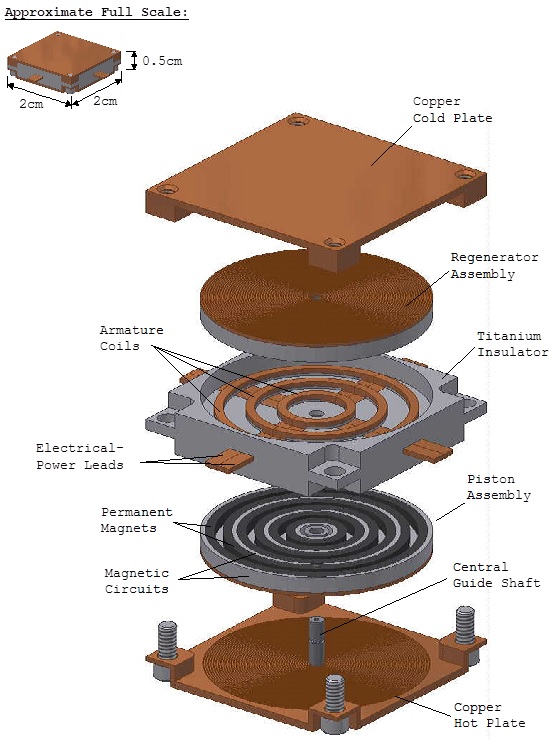

Figure 1. Micro-Stirling Active Cooling Module (MS/ACM) for Microelectronics

The Department of Defense (DoD) has many systems that can benefit from the features of a cm-scale micro-refrigerator. Under a DARPA contract, we are developed a cm-scale Micro-Stirling Active Cooling Module (MS/ACM) micro-refrigerator to benefit the DoD systems (see Figure 1 above). Our MS/ACM uses miniaturized versions of components we have already developed for space-based cryocoolers for the MDA and the AFRL, including our technologies for: (1) Ultra-Compact Recuperators (UCRs); (2) reliable friction-free fluid-film bearings; and (3) precision-manufacturing processes. Stirling coolers are highly efficient and compact. For example, the high efficiency and compactness (and lightweight) of Stirling coolers have made Stirling coolers the dominant type of cooler for cooling space-based electronics. In theory, the Stirling refrigeration cycle can achieve the Carnot COP (the maximum possible COP) of 11.5 for a cooling-load temperature of 15 C and a heat-sink temperature of 40 C. Practical considerations limit actual COPs to smaller values, but a COP better than 3 seems achievable. Under the DARPA contract, we are designed a breadboard MS/ACM and demonstrated critical fabrication techniques. Fabrication of our MS/ACM requires precision High-Speed Machining (HSM) and micro-machining processes.

The Department of Defense (DoD) has many systems that can benefit from the features of a cm-scale micro-refrigerator. Under a DARPA contract, we are developed a cm-scale Micro-Stirling Active Cooling Module (MS/ACM) micro-refrigerator to benefit the DoD systems (see Figure 1 above). Our MS/ACM uses miniaturized versions of components we have already developed for space-based cryocoolers for the MDA and the AFRL, including our technologies for: (1) Ultra-Compact Recuperators (UCRs); (2) reliable friction-free fluid-film bearings; and (3) precision-manufacturing processes. Stirling coolers are highly efficient and compact. For example, the high efficiency and compactness (and lightweight) of Stirling coolers have made Stirling coolers the dominant type of cooler for cooling space-based electronics. In theory, the Stirling refrigeration cycle can achieve the Carnot COP (the maximum possible COP) of 11.5 for a cooling-load temperature of 15 C and a heat-sink temperature of 40 C. Practical considerations limit actual COPs to smaller values, but a COP better than 3 seems achievable. Under the DARPA contract, we are designed a breadboard MS/ACM and demonstrated critical fabrication techniques. Fabrication of our MS/ACM requires precision High-Speed Machining (HSM) and micro-machining processes.