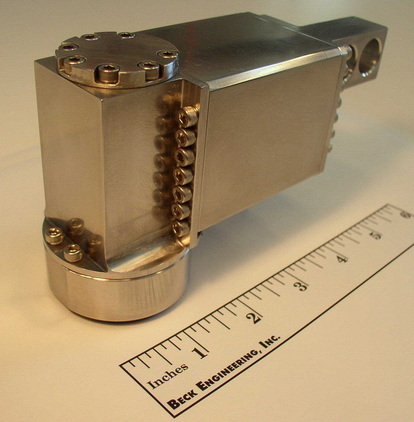

Figure 1. Our Vacuum Nose Lock Drill End-Effector (VNL/DEE)

The Air Force needs a flexible robotic drilling system for drilling and countersinking holes in JSF inlet ducts. Under a Phase I SBIR contract with the Air Force, we designed, built, and demonstrated a compact Vacuum Nose-Lock/Drill End-Effector (VNL/DEE), which is a critical component of a flexible robotic drilling system. The picture above shows the VNL/DEE we designed, built, and demonstrated. A fluid turbine drives the shaft of our VNL/DEE, and hydrostatic (water) bearings support the shaft. We drilled a ¼ inch hole through a graphite-epoxy composite material sample, to demonstrate our VNL/DEE. Robots can accurately position drills, but robots lack rigidity required during drilling, so hole quality is poor. On the other hand, the Vacuum Nose-Lock (VNL) of our drill provides maximum rigidity, so our VNL/DEE can produce high-quality holes.

The Air Force needs a flexible robotic drilling system for drilling and countersinking holes in JSF inlet ducts. Under a Phase I SBIR contract with the Air Force, we designed, built, and demonstrated a compact Vacuum Nose-Lock/Drill End-Effector (VNL/DEE), which is a critical component of a flexible robotic drilling system. The picture above shows the VNL/DEE we designed, built, and demonstrated. A fluid turbine drives the shaft of our VNL/DEE, and hydrostatic (water) bearings support the shaft. We drilled a ¼ inch hole through a graphite-epoxy composite material sample, to demonstrate our VNL/DEE. Robots can accurately position drills, but robots lack rigidity required during drilling, so hole quality is poor. On the other hand, the Vacuum Nose-Lock (VNL) of our drill provides maximum rigidity, so our VNL/DEE can produce high-quality holes.