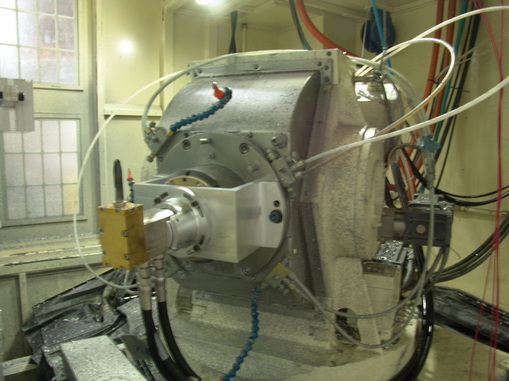

Figure 1. Our Compact High-Speed High-Power Right-Angle Milling Head (HSHP/RAMH)

Under a Phase II SBIR contract with the Air Force Research Laboratory (AFRL), we developed a Compact High-Speed (30,000 RPM) High-Power (2 hp) Right-Angle Milling Head (HSHP/RAMH) for machining complex geometries in aircraft structures. Our HSHP/RAMH uses hydrostatic bearings, direct fluid-turbine drive, and our proprietary toolholder system. We use our proprietary advanced manufacturing techniques to fabricate the parts of our HSHP/RAMH. As a Phase II subcontractor, a major defense aircraft integrator demonstrated a reduced-power prototype HSHP/RAMH by conducting milling tests. The subcontractor also conducted tap tests of our HSHP/RAMH, and the tap tests (tap tests experimentally identify the dynamic compliance of the spindle/toolholder/tool system) indicate the full spindle power (2 hp) can be used for chatter-free milling of aluminum with important tools. Current machine tools cannot efficiently mill aircraft structures with integral return flanges and other complex internal features. Our spindle will enable efficient milling of the complex features.

Under a Phase II SBIR contract with the Air Force Research Laboratory (AFRL), we developed a Compact High-Speed (30,000 RPM) High-Power (2 hp) Right-Angle Milling Head (HSHP/RAMH) for machining complex geometries in aircraft structures. Our HSHP/RAMH uses hydrostatic bearings, direct fluid-turbine drive, and our proprietary toolholder system. We use our proprietary advanced manufacturing techniques to fabricate the parts of our HSHP/RAMH. As a Phase II subcontractor, a major defense aircraft integrator demonstrated a reduced-power prototype HSHP/RAMH by conducting milling tests. The subcontractor also conducted tap tests of our HSHP/RAMH, and the tap tests (tap tests experimentally identify the dynamic compliance of the spindle/toolholder/tool system) indicate the full spindle power (2 hp) can be used for chatter-free milling of aluminum with important tools. Current machine tools cannot efficiently mill aircraft structures with integral return flanges and other complex internal features. Our spindle will enable efficient milling of the complex features.