In addition to machining parts for our in-house R&D work, we also perform cutting-edge machining services for government and corporate clients. We welcome Requests For Quote (RFQs) for the most-challenging parts.

The picture above shows our 10,000 square foot building. Our building includes:

5,000 s.f. Office/Lab. We have 5,000 square feet of temperature-controlled office/lab space in which we: assemble and test equipment developed under contracts with the government; perform engineering calculations; and manage the government contracts.

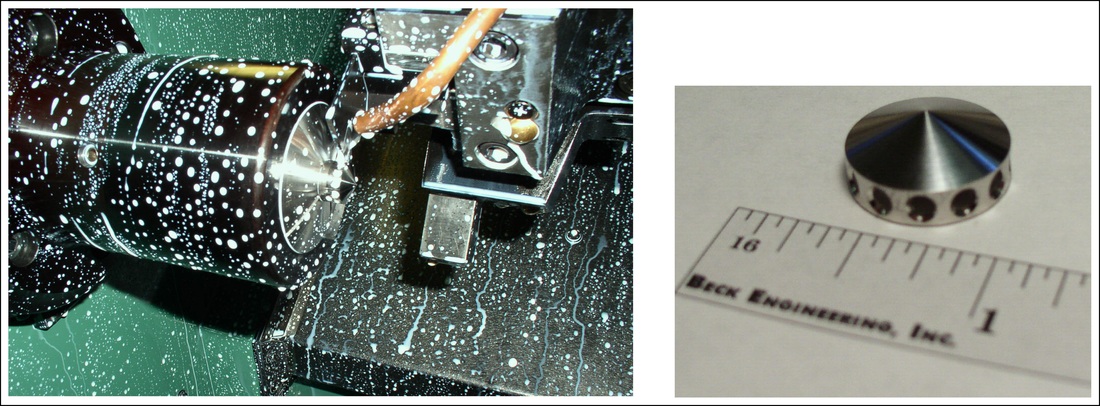

5,000 s.f. Machine Shop. We have a 5,000 square foot temperature-controlled machine shop that includes state-of-the-art Computer Numerically Controlled (CNC) machine tools and precision manual machine tools: two CNC turning centers (lathes); a CNC Vertical Machining Center (VMC); a CNC milling machine; a Hardinge HLV-H Super-Precision toolroom lathe; a 16” ´ 40” (swing ´ distance between centers) engine lathe; a heat-treating oven; welding and brazing equipment; a Sunnen MBB-1660 bore-finishing honing machine; various grinding and finishing machines and equipment. Figure 1 shows one of our CNC turning center (lathe) producing a poppet of our high-speed poppet check valve, and Figure 2 shows the poppet. Figure 3 shows our CNC VMC making parts in volume; and Figure 4 shows our CNC milling machine machining a piece of a magnetic circuit of a space-based cryocooler.

The picture above shows our 10,000 square foot building. Our building includes:

5,000 s.f. Office/Lab. We have 5,000 square feet of temperature-controlled office/lab space in which we: assemble and test equipment developed under contracts with the government; perform engineering calculations; and manage the government contracts.

5,000 s.f. Machine Shop. We have a 5,000 square foot temperature-controlled machine shop that includes state-of-the-art Computer Numerically Controlled (CNC) machine tools and precision manual machine tools: two CNC turning centers (lathes); a CNC Vertical Machining Center (VMC); a CNC milling machine; a Hardinge HLV-H Super-Precision toolroom lathe; a 16” ´ 40” (swing ´ distance between centers) engine lathe; a heat-treating oven; welding and brazing equipment; a Sunnen MBB-1660 bore-finishing honing machine; various grinding and finishing machines and equipment. Figure 1 shows one of our CNC turning center (lathe) producing a poppet of our high-speed poppet check valve, and Figure 2 shows the poppet. Figure 3 shows our CNC VMC making parts in volume; and Figure 4 shows our CNC milling machine machining a piece of a magnetic circuit of a space-based cryocooler.

Figure 1. Our CNC Turning Center Producing a Poppet Figure 2. The Poppet

Figure 3. CNC Vertical Machining Center (VMC) Figure 4. CNC Mill