- Store

- >

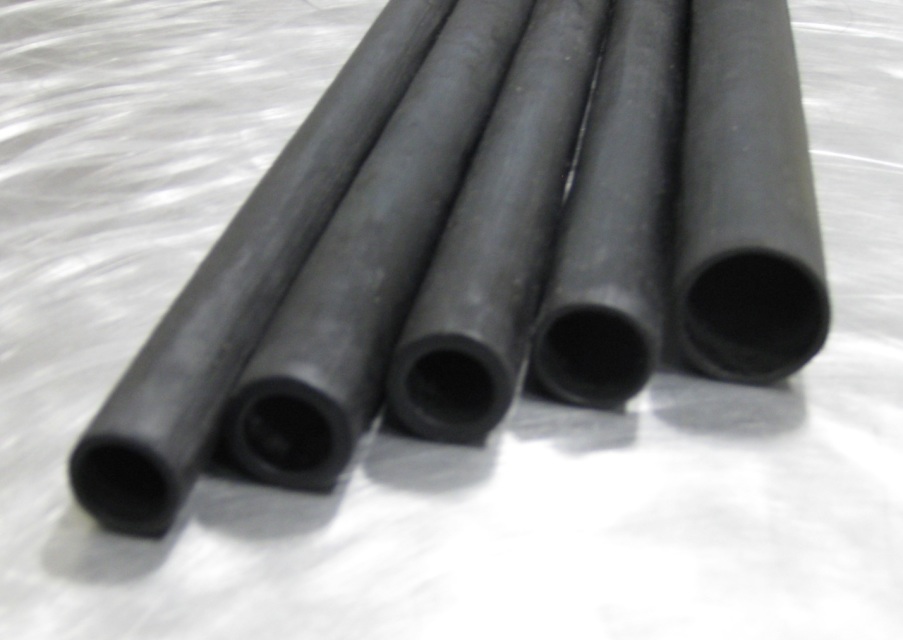

- Carbon Fiber Reinforced Polymer (CFRP) Structural Tubes

- >

- Carbon Fiber Reinforced Polymer (CFRP) Structural Tubes

Carbon Fiber Reinforced Polymer (CFRP) Structural Tubes

SKU:

$27.00

26

108

$26.00 - $108.00

Unavailable

per item

- Optimized for maximum strength-to-weight ratios.

- Optimized for maximum bond strength.

- No stress concentrations.

- Lowest prices in the industry.

- Custom sizes expedited: please contact us.

Inside Diameters (IDs) Available:

- 1/2 inch to 1 inch nominal IDs.

- Please contact us for custom diameters.

Wall Thicknesses Available:

- 0.051 inch to 0.137 inch.

- Please contact us for custom wall thicknesses.

Lengths Available:

- 3 foot random lengths.

- Please contact us for custom lengths.

Typical Mechanical Properties*:

- Tensile strength up to 401 ksi.

- Tensile modulus up to 22 Msi.

- Shear modulus typically 0.73 Msi.

- Density typically 1.6 g/cm3.

*The listed typical mechanical properties are projected values, based on the type of CFRP raw material used, our proprietary manufacturing process, etc. Test data is coming soon.

Our Carbon Fiber Reinforced Polymer (CFRP) Structural Tubes):

Our Carbon Fiber Reinforced Polymer (CFRP) structural tubes have the following advantages over tubes offered by our competitors:

1. Optimized for Maximum Strength-to-Weight Ratios. We have optimized the designs of our CFRP structural tubes for maximum strength-to-weight ratios. Unlike tubes offered by our competitors, our structural tubes contain no decorative plies nor coatings: every fiber and gram of our tubes contributes to structural strength. Our tubes contain mostly 0˚ (axially aligned) plies, with one 90˚ ply near the inside diameter and a second 90˚ ply near the outside diameter, to provide hoop stability.

2. Optimized for Maximum Bond Strength. Our competitors sell tubes with 90˚ plies on the Inside Diameter (ID) and on the Outside Diameter (OD); however, adhesive bonds have greatest strength when the parts have fibers axially aligned on the bonded surfaces. Our CFRP structural tubes have fibers axially aligned on the ID and the OD, to maximize bond strength.

3. No Stress Concentrations. Our competitors consolidate tubes with heat-sensitive “shrink tape.” Shrink tape leaves helical grooves around the tube ODs, which provide stress concentrations that limit the bending, tensile, and compressive strengths of our competitors’ structural tubes. On the other hand, our proprietary manufacturing process produces no stress concentrations in the hoop direction, so the structural strengths of our tubes are not limited by stress concentrations.

4. Lowest Prices in the Industry. Our proprietary manufacturing process not only produces superior CFRP structural tubes, but our proprietary manufacturing process also enables us to produce tubes at lower costs than our competitors, so we can offer CFRP structural tubes for the lowest prices in the industry.